Engine Reconditioning

With over 45 years’ experience reconditioning engines, you can be assured your engine is reconditioned to the highest standards. Our knowledge and precision machinery mean you can be confident in the longevity of your reborn engine. Don’t risk your pride and joy with backyard boys.

Phillip Heads offers a free detailed inspection and quote. We’ll let you know the most economical and flawless way forward with your engine rebuild.

Rebore & Honing

Generally, most engine blocks will only need honing however, sometimes a rebore is required if there is too much lip or the bore isn’t perfectly round. A rebore is a process of cutting away metal with a carbide cutting tool.

Honing is a similar process, however, using stone to remove much smaller increments. Most damaged cylinders can be bored out, honed and have oversized pistons and rings installed.

Something like a damaged aluminium block with integral iron sleeves might require re-sleeving to save the block. If cylinder bores are too badly damaged, buying a new or donor block is sometimes more economical.

Before wasting your time and money, get a free detailed inspection and quote from the boys at Phillip Heads.

Cylinder Block Decking

Cylinder block decking is the process of cutting down the part of the block that meets the cylinder head. It’s essential to ensure the surface is perfectly flat to achieve a good head gasket seal and the cylinder heads “square up”, and the block is perpendicular to the crankshaft centreline.

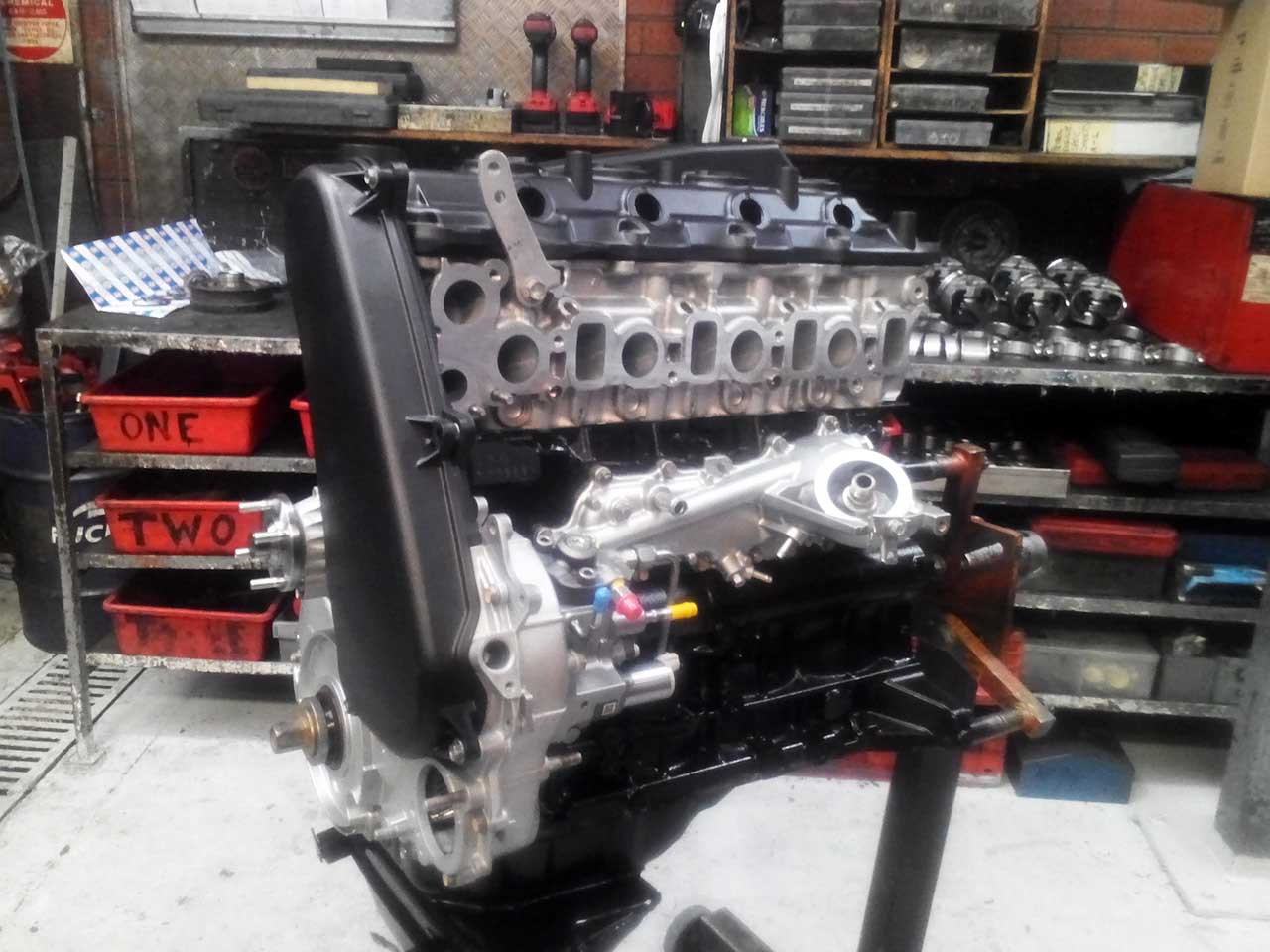

Cylinder Head Reconditioning.

Cylinder head reconditioning involves disassembling, cleaning, inspecting, and replacing various components of the head along with machining out any warps and imperfections on the head and/or valve train. See Cylinder Head Reconditioning for more information.

Crankshaft Grinding

The crankshaft is one of the most expensive parts of an engine to replace. It has a variety of forces acting on it, so ensuring it is in perfect condition is the most vital part of any engine rebuild.

So, unless you’re putting in a new crankshaft, your engine crankshaft should be inspected and measured. It will most likely require some grinding, depending on the age and abuse it has experienced.

After a lot of km’s, the play between the crankshaft and bearings becomes too much. Lowering oil pressure and lubrication and, in turn, increasing the rate that the crankshaft will wear out and the chance of it possibly breaking.

The two primary forces acting on a crankshaft are torsional and bending stresses.

- Torsional stresses are the total of all the twisting forces on the crankshaft. The crankshaft acts as a torsion bar, twisting one way and then the other as the pistons stop at the bottom and top dead centre while rotating at a consistent speed.

- The second force applied to the crankshaft is bending stress. The bulk of this is from the cylinder head pressure due to the combustion process. The bending load occurs at each rod pin when the cylinder fires. This is transferred to the mains on either side of the rod pin. However, it’s the crankshaft web that deflects the load. That’s why a crankshaft will usually break at the fillet radius if it is overloaded.

So, with all these torsional and bending stresses trying to break your crankshaft, wouldn’t grinding it down affect the strength? The answer is no, not by much if it’s done correctly.

Most crankshafts can be ground down to make it round again, and oversized bearings are used to ensure everything fits sweetly again. However, if there’s been too much damage or wear, it will have to be replaced.